Electric motors are at the heart of numerous industrial and commercial applications. The efficiency and performance of these motors heavily rely on the quality and design of their components, particularly the windings. Among the many winding configurations, DPE windings stand out as a cost-effective yet efficient solution for industrial motors. But what are they, and why are they important in the world of electric motor technology? In this article, we will dive deep into the world of DPE windings, exploring their design, benefits, applications, and the significant role they play in improving motor efficiency and reducing costs.

What Are DPE Windings?

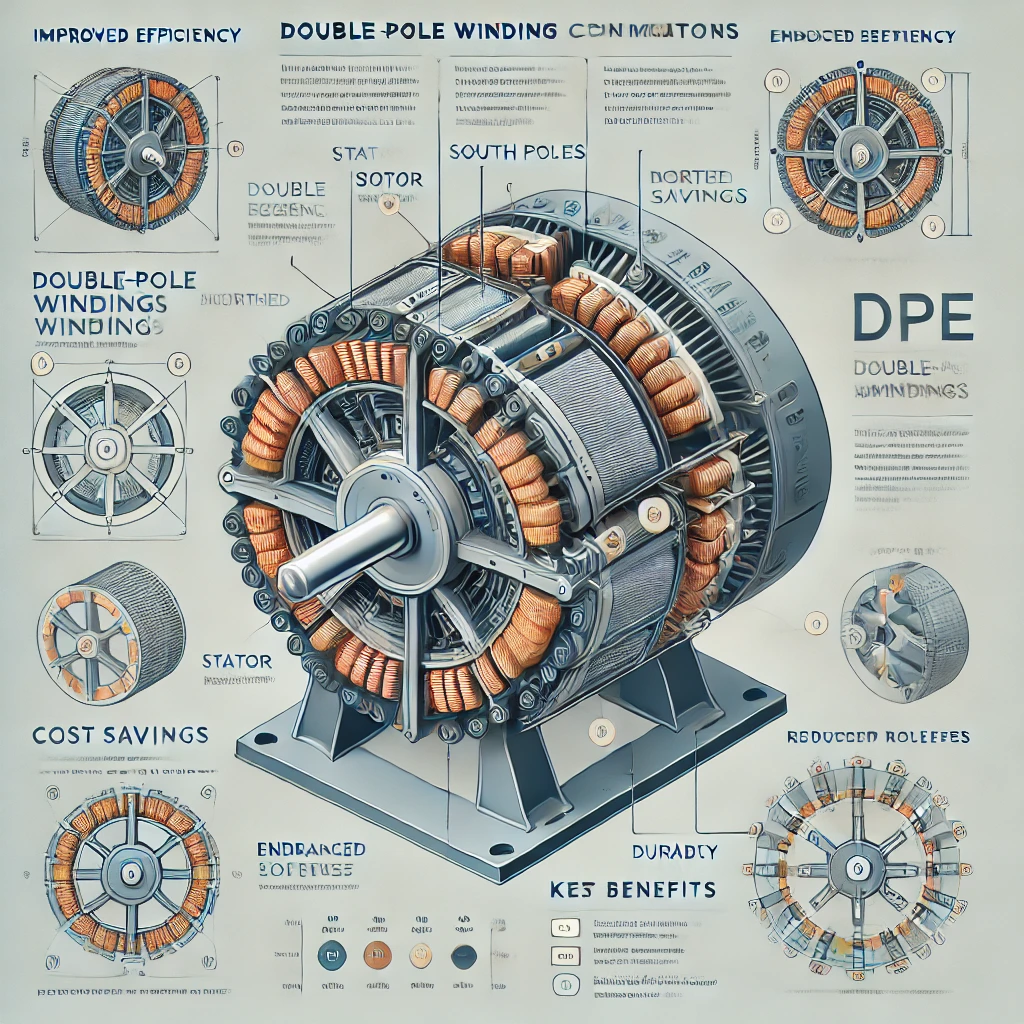

DPE windings refer to Double-Pole Econo windings, a specialized design used in electric motors. These windings are typically found in industrial-grade motors that require a balance between efficiency and cost-effectiveness. The term “double-pole” refers to the magnetic field created by the winding configuration, which uses two poles (North and South) to generate a rotating magnetic field. The “Econo” part of the name signifies the winding’s optimized, economical design, ensuring that the motor operates efficiently without incurring high production or energy costs.

The key idea behind these windings is to improve the performance of motors while keeping costs manageable. They achieve this by utilizing a clever design that enhances torque production, reduces energy consumption, and extends the motor’s lifespan, all while keeping manufacturing costs lower compared to more complex winding configurations.

The Design and Structure of DPE Windings

To better understand what DPE windings are, it’s crucial to look at their design. The winding of an electric motor is the component that generates the electromagnetic field necessary for the motor’s operation. In a DPE winding system, the stator is wound in such a way that it has two poles, which are strategically placed to enhance the magnetic interaction between the stator and rotor.

The “double-pole” design means that the winding arrangement creates two poles (North and South) within the motor, which work together to create a more stable and efficient electromagnetic field. The specific configuration helps to improve the torque produced by the motor while reducing power losses that typically occur with less optimized designs.

The “Econo” part of the windings refers to the use of materials and design principles that reduce manufacturing and operational costs. Instead of using more expensive materials or overly complicated winding designs, the system takes a more cost-effective approach while still delivering reliable performance. The use of optimized wire gauges, insulation, and efficient winding patterns helps in reducing the overall costs of motor production and operation.

Read Also: 970 Turbo PDK Transmission Filter and Fluid Change Guide: Tips and Costs

Benefits of DPE Windings

Now that we know what these windings are and how they are designed, let’s explore the benefits of using this type of winding in electric motors.

Improved Efficiency

One of the primary benefits of this windings is their ability to improve the efficiency of electric motors. The double-pole configuration generates a more efficient magnetic field, which translates into less energy wasted during motor operation. As a result, motors with these windings consume less power for the same output compared to conventional windings.

Cost Savings

The “Econo” aspect of DPE windings plays a critical role in cost savings. By optimizing the design and materials used, manufacturers can produce motors with these windings at a lower cost compared to motors with more complex winding configurations. This reduced production cost makes these windings an attractive option for companies looking to balance motor performance with budget constraints.

Enhanced Performance

DPE windings are designed to optimize the torque produced by the motor. The double-pole configuration allows for a more stable and consistent magnetic field, which results in better overall performance. Motors with these windings tend to have smoother operation, lower vibration, and a more balanced output, all of which contribute to the motor’s longevity and reliability.

Durability and Longevity

The efficiency of this windings also contributes to the motor’s longevity. Because these windings generate less heat during operation, they reduce the stress placed on the motor’s components. The lower operating temperatures prevent wear and tear, ultimately extending the life of the motor. Additionally, the economical design of the windings means that there is less chance of component failure, further improving the motor’s durability.

Reduced Power Losses

Traditional winding designs can suffer from power losses due to inefficient magnetic field generation or excessive heat buildup. DPE windings, however, are designed to minimize such losses. The optimized pole configuration and material choices work together to reduce energy losses, which means that more of the input power is converted into useful mechanical energy. This results in a motor that operates with greater energy efficiency and less wasted power.

Applications of DPE Windings

DPE windings are widely used in industrial motors, particularly in applications where efficiency, durability, and cost-effectiveness are essential. Here are some of the most common applications:

- HVAC Systems: DPE windings are commonly used in motors for heating, ventilation, and air conditioning (HVAC) systems.

- Pumps and Compressors: These windings are also found in motors for pumps and compressors across various industries.

- Manufacturing Equipment: Motors in manufacturing settings often feature DPE windings to drive conveyor belts, robotic arms, and more.

- Electric Vehicles (EVs): As demand for electric vehicles rises, DPE windings are being used in EV motors for their efficiency and cost-effectiveness.

DPE Windings vs. Traditional Windings

When comparing this winding to traditional winding designs, the advantages of the DPE configuration become clear. Traditional windings often require more intricate manufacturing processes and can be less efficient in terms of energy usage. In contrast, these windings achieve high efficiency through a simple yet effective design, reducing both production and operating costs.

The Future of DPE Windings

As the demand for energy-efficient solutions continues to grow, these type of windings are likely to play an increasingly important role in the development of electric motors. Innovations in materials, manufacturing techniques, and motor design will continue to improve the performance and cost-effectiveness of this windings, making them even more attractive to industries that rely on motor-driven systems.

Conclusion

In conclusion, DPE windings represent a significant advancement in electric motor design, offering a combination of efficiency, cost-effectiveness, and durability. By understanding what they are and how they work, industries can make informed decisions about their motor systems, leading to better performance and reduced operating costs. Whether in HVAC systems, manufacturing equipment, or electric vehicles, these windings are an essential component for achieving sustainable, efficient, and affordable motor-driven solutions. As technology continues to evolve, the role of this windings in shaping the future of motor design will only grow more significant.